Julien Bergounhoux | 19 January 2017 L’USINE DIGITALE

How are Peugeot, Citroën or DS cars born? They take shape within the Automotive design network, the DNA of the PSA group. Diving in the heart of this center and the process of designing the group’s vehicles, which goes from the most high-tech to the most traditional methods.

Virtual reality has been a real renaissance in recent years, particularly with the consumer market. But the major automobile, aerospace and shipbuilding industries have been using it for decades to design their aircraft. Philippe Deren, in charge of digital tools within the PSA Group’s design department, explains for L’Usine Digitale its place within the group’s “design process” and how it coexists with traditional techniques.

The Immersive Room center of Vélizy, flagship of the digital creation device of PSA. © Julien Duhem

A design direction

The design department within the PSA Group has around 360 people, divided by brand: Peugeot, Citroën and DS. Each team has its particularities and its director of design.

“My team and I provide all the means related to design, from the stylus for Photoshop to the milling machine for a clay model, explains Philippe Deren, between these two uses, there are also many other tools, such as software. ICEM Surf from Dassault Systèmes, widely used to generate the bezier surface in the car. “

Visualization material is essential among these tools. The PSA group has invested in these technologies since 1999, and has spent more than 7 million euros in this area over the years. A sum quickly profitable. “We have immersive systems in Sochaux, Rennes and Vélizy,” says Philippe Deren. The center of Vélizy, opened in 2004, is the flagship of the group, and bears the evocative name of Automotive Design Network (ADN).

“The work starts on 24-inch screens and then we go to the 1: 1 scale,” continues Philippe Deren, “we have about fifteen rooms with screens 5 meters wide by 2 meters long. high with overhead projectors, most of which are in 4K resolution.” Some are installed by the Bordeaux integrator Immersion, but most are managed directly by the Belgian manufacturer Barco. A good part of these rooms are in classic 2D, but some can do passive or active stereoscopy.

These rooms can hold up to twenty people. They are used both for work sessions and for presentations to company executives. Carlos Tavares, the group’s president, comes here every month to do design reviews. “The room really dedicated to employers has 18 meters of screen (with three screens of 6m x 3m). It allows to project three images or image banks to make large presentations,” adds the engineer. This device is complemented by an Immersive Room with five faces and a Holospace with three faces. They stereoscopically tracked and thus offer a form of virtual reality indoors. “The interest for our teams is to inspect a vehicle under better views and at full size.”

From virtual reality … to clay sculpture

The designers validate their choices in virtual and make all the necessary technical modifications. But the final validation is done on physical models, milled in polystyrene or clay on a 1: 1 scale. “We do not want to validate everything in digital, the physical stage is essential,” says Philippe Deren, “We also use 3D printers in the meantime to make illustrations on specific parts, such as vehicle interiors: dashboards, caps , aerators, radio facades … “

Once the milling is done, the designers make manual retouches, which are then scanned by stereophotometry to be reintegrated into digital. “We’re scanning a cloud of points,” he says, “we’re validating that it’s stable, that it fits in well, and some things are done on clay more easily than on screen.” From the blank sheet to the marketing of the product, the process takes between 3 and 4 years. “The purely creative phase usually takes 18 months, says Philippe Deren, and then industrialization.”

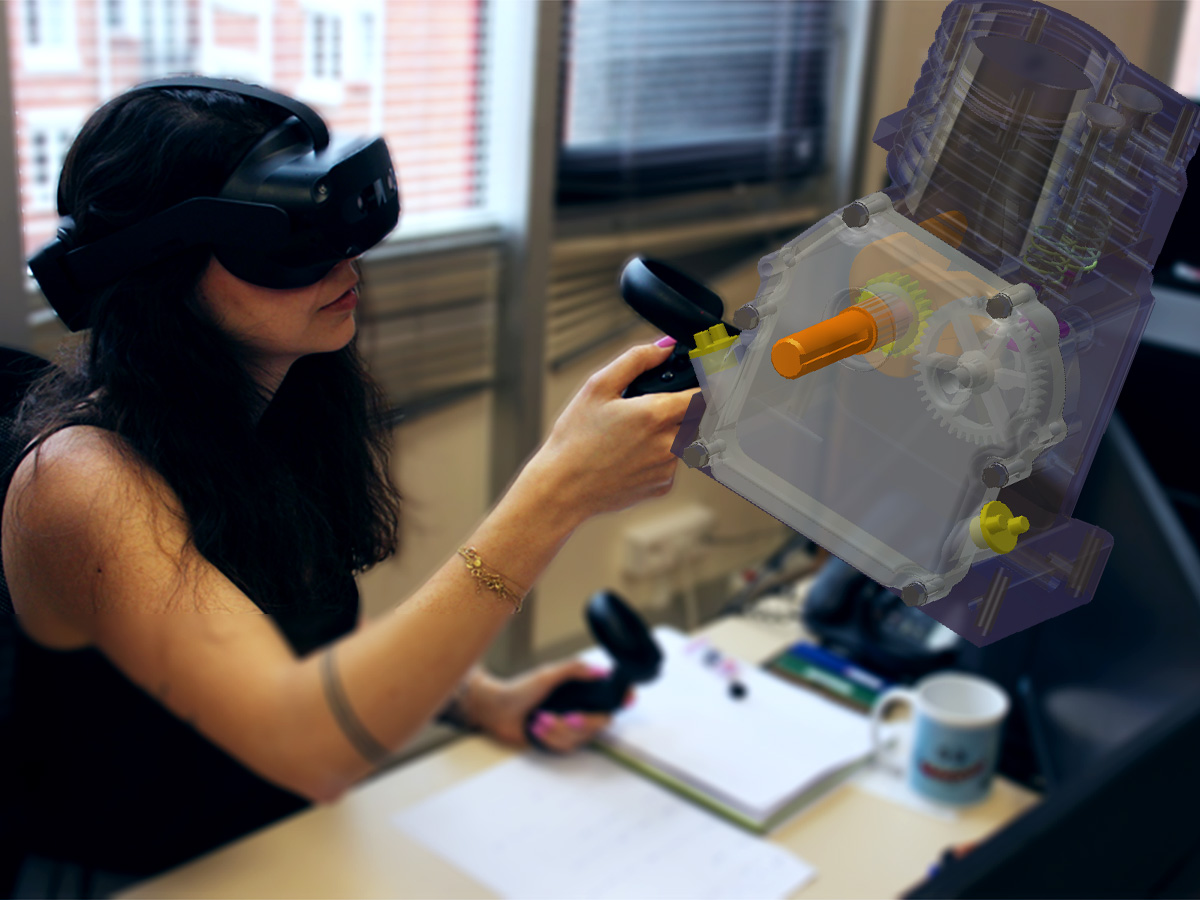

Consumer headsets on trial

The dynamic of the virtual reality sector is on the Headset side, it is not a mystery. It is therefore no surprise that we learn that PSA closely follows their evolution. “We have been watching virtual reality headsets for some time and the HTC Vive has caught our attention.” It must be said that a Immersive Roomcosts several million euros and a Holospace is worth several hundreds of thousands (just like a 1: 1 scale screen). “And the maintenance of the projectors has a cost,” adds Philippe Deren, “that’s why we switch to laser: there will be no more lamps and the service life is 10 years.” In comparison, a Vive “Business Edition” costs 1150 euros.

In addition, designers and directors promote the development of digital tools, because the physical models have a significant cost and take several weeks to arrive, while a 3D model is immediately ready. The group is testing three HTC Vives for the moment, and will deploy more if the test phase is conclusive. However, the services offered by this first generation of consumer headphones do not yet fully meet the needs of PSA after Philippe Deren. “They are much cheaper, have good immersion, and are light and stable, but there are still barriers to their integration into our design process.”

Software compatibility provided by TechViz

The first problem is the lack of native software compatibility with these devices. While Dassault Systèmes recently integrated a VR visualization module directly into Catia v6, this is not yet the case for other applications such as 3DExcite or ICEM Surf. “The first ideas and the first choices can be made with helmets, it simplifies things because we have only one Immersive Room and it has a schedule of use.But it can not be done if it is necessary to pass We are in automotive design with very complete models and specific needs. “

To mitigate this problem, PSA adopted at the end of 2016 a solution of the specialist TechViz, a supplier whose software for Immersive Room it had already been using since 2006. It allows to directly display in their helmets all the software of the market, and in this case 3DExcite, ICEM Surf, but also 3DExperience or Catia v5. No data conversion required, no specific preparation.

![PSA Velizy powerwall]()

Headset and Immersive Room, complementary tools

The second weakness of headset over conventional equipment is their current limitation in rendering quality. The resolution is too low for the design and creates issues with pixelization on the inside (grain of the textures, sharpness of the displays) and the outside (display of two or three vehicles at a certain distance) of the cars. “Maybe with the second generation of headphones it will be better when they have a resolution of 10K. After, it will be necessary to see what power of display is necessary to not have latency on our 3D models,” comments Philippe Deren. This limits their field of application for the moment.

Remote collaboration not optimized enough

This same latency (delay between a movement of the head and its repercussion in the virtual environment) is also a problem for remote collaboration, according to Philippe Deren. “Telepresence between remote sites has its limits. For our designers located in Shanghai, we share a 3D model on which everyone works on their side, in telepresence, but not with stereoscopic view. This could bring something, it would be the next step, but the limits of latency are already present in France, on conventional systems, while we are on the internal PSA network. That is why today we limit ourselves to Skype for Business and Webex …”La collaboration à distance pas assez optimisée

If interest is present, virtual and augmented reality headsets will not replace existing tools anytime soon. Nevertheless, as technology evolves, they should become increasingly important in the design process. See you in five years to gauge this evolution.