Maintenance in VR

Thanks to Virtual Reality, maintenance is no longer an afterthought in the development of a new product or facility.

TechViz has 2 key use cases in VR maintenance:

- During the development phase, evaluation of maintenance scenarios

- During the operation phase, remote assistance for maintenance

Evaluation of maintenance scenarios

Determining how to maintain an installation, repair or replace a component in crowded or tight environments – such as a submarine compartment or an aircraft engine pylon – used to be a challenge. During the development phase, physical mock-ups were to be built and design teams were struggling to keep them updated with the latest design modifications.

Now, operational reliability and direct maintenance costs can be reduced significantly thanks to the evaluation of maintenance scenarios in VR.

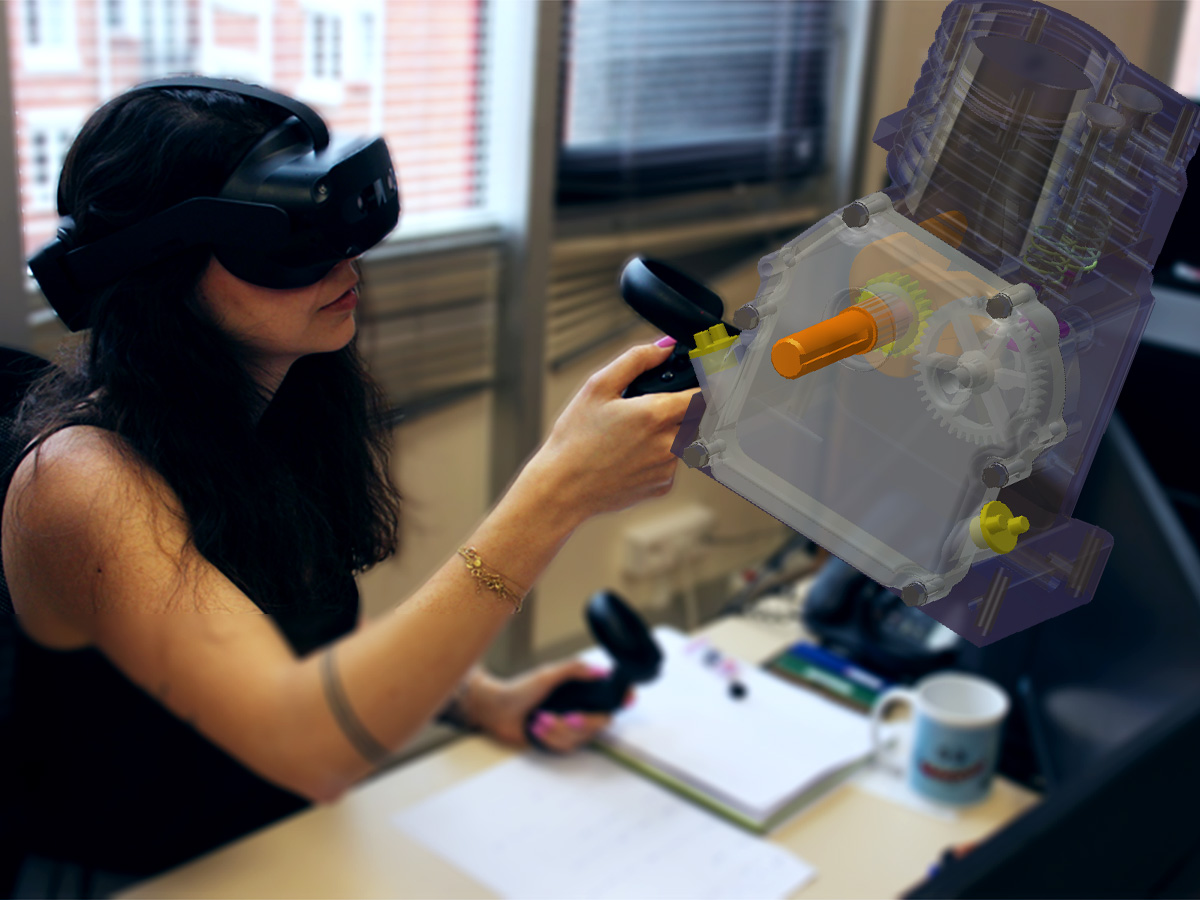

TechViz 3D visualization software can be used to to assess the maintenance scenarios of a future installation. Even in the early stages of development, it is possible to check the feasibility of any operation and the ergonomic posture of the technician while he performs it. Preparedness is also greatly improved as all kinds of adverse events can be addressed and the adequate response properly tested.

VR remote assistance

When an incident occurs in an installation, the engineering team responsible to fix it can sometimes be located halfway across the globe. Additionally, working conditions in many facilities can be complex or even dangerous. Therefore, simulating and reproducing the situation in a safe environment, with the remote assistance of supporting engineers brings real benefits. It both reduces the risks of the intervention and the downtime of the installation.

Thanks to VR collaboration tools, engineers and on-site staff can literally meet inside the CAD model of the installation. They can use VR remote assistance, and walk technicians through a step-by-step procedure of what needs to be done to solve the incident and be fully ready for a safe and quick intervention on the actual facility.

A simple and iterative process

Just load the model in the native software (like PTC Creo) and TechViz will display the model immediately in any VR System (like a CAVE or an HTC Vive). The team is then able to perform immediately the maintenance operation, for training or ergonomic assessment purpose. Supporting engineers are able to advise the technician to try to perform the operation differently. During the development phase, they can test the impact of changes on the configuration of the installation in real-time. By using the native software, it is possible to immediately check the change, find the best configuration and back it up in the native PDM system. Such virtual assessment enables to perform in hours a process that would have lasted weeks by doing mockups or 3D model conversions.

TechViz VR software is also packed with features to integrate the human into the scene and make VR maintenance assessments as easy and precise as possible.